The camera, powered by a cooled mercury cadmium telluride detector, can effectively detect radiation changes in the 3.0µm to 3.5µm band of the spectrum. This article takes a closer look, based on product testing by a&s China.

Hikvision’s gas cloud monitoring camera is powered by a cooled mercury cadmium telluride detector, which can effectively detect radiation changes in the 3.0µm to 3.5µm band of the spectrum, allowing invisible volatile organic compound (VOC) gases to appear in the video screen. This article takes a closer look, based on product testing by a&s China.

In chemical plants, gas leakages bring great safety hazards. Staff need to conduct daily inspections to inspect gas transmission pipelines to ensure the tightness of each sealing position. To meet the needs of real-time VOCs detection, Hikvision has launched their gas cloud monitoring camera (hereafter referred to as “gas cloud camera”). This camera can monitor dangerous hydrocarbon gases, locate leak sources, and display the trajectory of leaked gases in real time. The camera improves the efficiency and convenience of hazardous gas detection with its long-distance, non-contact VOCs gas monitoring method.

Rock solid and explosion-proof

The appearance of the gas cloud camera is significantly different from that of traditional cameras. Its shell is mainly made of 316L stainless steel, giving strong protection to the device. At the same time, the surface of the camera is coated with an anti-corrosion coating, which can effectively resist corrosive agents and interference from gas or solutions. It is precisely because of this design that the camera has an IP68 protection level and meets the Exd IIC T6 Gb/ExtD A21 IP68 T80°C explosion-proof standard.

The product has a PTZ structure, with the gas cloud camera unit on the left and a visible light camera unit on the right. Both cameras are equipped with light hoods on the top to avoid interference from sunlight or rain, and the visible light camera is equipped with a wiper to clean up debris when needed.

Under the visible light camera sit the high-power infrared fill light and white fill light, which can illuminate the area within a range of 200 meters.

The camera can achieve 360° continuous rotation in the horizontal direction and a vertical range of -90° to 90°. In a&s’ product testing, it can be found that the gas cloud camera rotates smoothly without lag. The horizontal rotation speed can be controlled at 0.1°-25°/s, and the vertical speed is 0.1°-10°/s. In order to better cover the scene, the camera can have 255 preset points or 8 cruise scanning lines.

At the bottom of the product, there are power cords, alarm input/output, network interfaces and other ports, allowing the camera to be used in a variety of environments.

Dual light synchronization

The Hikvision gas cloud imaging monitoring camera is equipped with a visible light unit and a gas cloud imaging unit. The visible light camera uses a 4MP 1/1.8" Progressive Scan CMOS, which not only allows the camera to achieve a resolution of 2560 × 1440 but also gives the camera good night vision capabilities.

At the same time, the camera is equipped with a 6-240 mm zoom lens. The 40x optical zoom allows the camera to achieve three-dimensional coverage of wide areas, and the 16x digital zoom enables effective monitoring of specific areas.

It is worth noting that the camera supports video output with a maximum resolution of 2560 × 1440 at 60 fps for the main stream, and 704 × 576 at 25 fps for sub-streams.

In addition, the visible light camera also supports ultra-wide dynamic range, backlight compensation, strong light suppression, 3D noise reduction, anti-shake and other functions, making it effective in various weather conditions and ultra-low illumination scenes. At the same time, the visible light camera has intelligent analytics capabilities that can effectively meet users’ various operational needs.

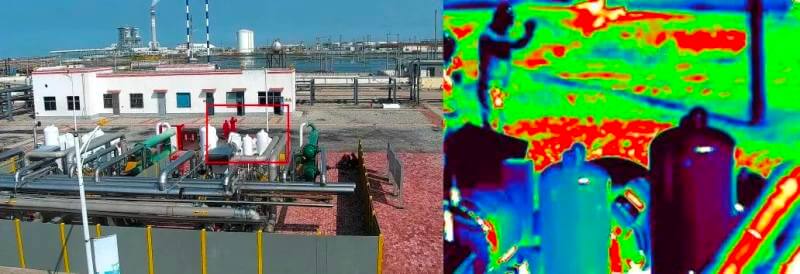

Product testing image

Product testing image

The gas cloud camera unit is equipped with a cooled mercury cadmium telluride detector and an F2.0 lens, allowing it to monitor VOCs in real time. The detector has a maximum resolution of 320 × 256 and can detect more than 50 hydrocarbons such as methane and ethylene in real time in low temperature environments.

With the highly sensitive cooled mercury cadmium telluride detector, the gas cloud camera can effectively detect VOC gases with an air mass diameter of 1 meter within 500 meters. In a&s’s product testing, it is not difficult to find that once VOCs are detected, an alarm can be generated in a short time, and the gas location can be marked.

To pinpoint the location of a VOC gas leak, the gas cloud camera can work with the visible light camera video to improve detection efficiency; in addition, since the gas cloud images are mainly black and white, the user can adjust the color setting to see a variety of colors, effectively avoiding visual fatigue.

Product testing image

Product testing image

The gas cloud camera has a 5x optical zoom, thereby improving its applicability in large scenes.

Product advantages

1. The visible light camera uses 4MP CMOS, which can achieve effective color capturing;

2. The visible light camera is equipped with a 40x optical zoom lens and 16x digital zoom, which can effectively cover various scenes;

3. The gas cloud camera uses a cooled mercury cadmium telluride detector, which can accurately detect VOC gases in -193°C environments and automatically report to the backend;

4. The gas cloud camera can be set up with a pseudo-color display to avoid visual fatigue or visual deviation;

5. The visible light camera can be integrated with the gas cloud camera to effectively improve detection and identification efficiency;

6. The camera allows high-precision pan/tilt with a maximum accuracy of 0.1°, stable movement without lag, and no jitters in the image;

7. The camera has its own backup capability, which effectively ensures data storage in the event of network and power outages;

8. The camera is made entirely of 316L stainless steel, with an anti-corrosion coating on the surface, which can effectively ensure the service life of the camera.

a&s review

With rapid development of chemical industries across the globe, how to protect the safety of chemical plant workers has become a core priority for enterprises. In order to ensure the safety of each area within the plant, operators usually arrange a large number of personnel to conduct comprehensive inspections of the area at different time intervals, but real-time inspections still need technology support.

In this regard, Hikvision’s gas cloud monitoring camera can come in handy. It is powered by a cooled mercury cadmium telluride detector that can effectively detect radiation changes in the 3.0µm to 3.5µm band of the spectrum, allowing invisible VOC gases to appear in the video. Through visible light fusion technology, the leak location can be intuitively located. With the camera, users can monitor various locations in large areas 24-7, greatly improving supervision efficiency.