Utilizing the Internet of Things, automating more processes and using analytics are all helping oil and gas companies improve operational efficiency, while also bringing them up to speed with the digital age.

Digital technologies are not new to the oil and gas (O&G) industry — they have been using various forms of digital tech for decades. However, according to some, up until now most of these digital initiatives have been rather conservative with limited impact on existing operating or business models.

Large-scale operations were the first to adopt digital technologies in the 1980s. Nowadays, with the popularization of the Internet of Things (IoT), and even the Internet of Everything (IoE), digitalization and things like automation are becoming a larger part of management and operations even in smaller-scale settings.

With the price of oil per barrel half of what it was five years ago, O&G companies are looking for ways to improve operational efficiencies to compensate for lower margins.

A survey conducted by Cisco found that more than half of the respondents thought the IoE could potentially automate 25 to 50 percent of manual processes within O&G industries. Production optimization was identified by 56 percent of respondents as the process with the most IoE-drive automation benefits, followed by maintenance and business operations. Furthermore, Oxford Economics estimates that increased digital adoption could result in global real GDP increase by up to 0.8 percent (US$816 billion) by the end of 2025. Basically, digitalization has the potential to create a tremendous amount of value for O&G companies. So what’s the hold up?

Digitalizing Oil and Gas

Low oil prices have resulted in the need to reduce costs and increase operational efficiency, and as a result digitalization has become a solution. “The digitalization of the oil and gas sector has been increasing rapidly the last few years with significant progress in digital technologies, including artificial intelligence, automation, predictive analytics and machine-to-machine communication,” said Magne Berg, Global Head of Processes and Systems at

DNV GL.

Joe McMullen, Marketing Director at

Schneider Electric, pointed out, “Oil and gas companies must recognize that the digital transformation isn’t a fad and won’t go away; those that choose not to invest in these new technologies stand to be at a significant competitive disadvantage.”

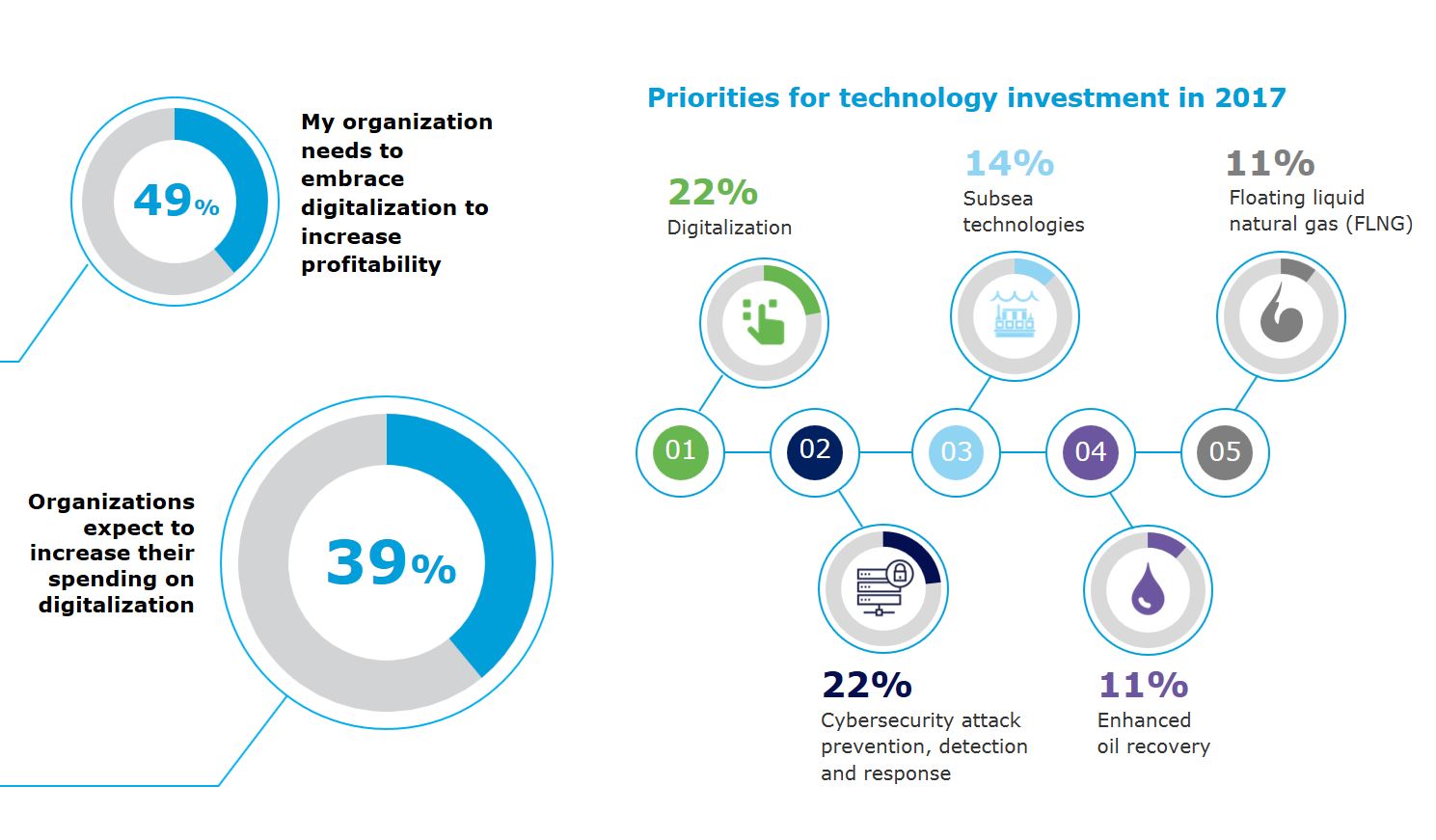

This year alone digitalization is expected to see significant growth in the O&G industry, according to DNV GL’s annual benchmark study on the outlook of the oil and gas industry. The report found 39 percent of the 723 senior sector players surveyed expect their organization’s spending on digitalization to increase in 2017. The low oil and gas sector is also expected to increase their focus on digitalization.

“The confluence of sensors, software, mobility and connectivity in the field is allowing operators who use these automation tools effectively to beat out their competitors by a long shot. Not only are they able to better control their costs, but they are also able to drive up their efficiencies,” said Hari Dutt, Senior Product Manager at

Seven Lakes Technologies.

Digitalization is on the rise in the oil and gas industry, becoming a top priority for technology investment in 2017.

Digitalization is on the rise in the oil and gas industry, becoming a top priority for technology investment in 2017.

Source:DNV GL Industry Outlook 2017

Innovation and Unlocking Data

New innovations in the O&G industry have been propelled by technological advances. Operators are looking for better ways to predict where they need to be before an event happens, as well as the ability to prioritize events already happening. This is possible with new technology.

“Prediction and prioritization both from a value-add perspective have become the key drivers in the industry, which can be derived from increased digitalization,” Dutt said.

McMullen explained, “Predictive analytics allows companies to better anticipate problems before they become an issue — becoming preventive with asset management instead of reactive. From an optimization perspective, access to data from across all operations lets users optimize operations based on a more holistic basis. In the past, it was virtually impossible to model or simulate interdependent processes on such a scale.”

The application of such analytics is possible with the abundance of data generated at any given O&G facility.

A report by PwC stated a single drilling rig can generate one terabyte of data each day. This amounts to the possibility of one petabyte (10^15 bytes) or more of data passing through an oilfield per day.

With this volume of data available, digitalization, IoT and machine learning are all providing the means to take this data and make use of it. And, the need to take advantage of this data has become more obviously apparent.

“The edge data collection process, of collecting seemingly unrelated and irrelevant data will have a significant impact on the productivity of the industry moving forward,” Dutt said. “As deep learning neural nets can use data to make automated, near real-time decisions in the field, operators will now have access to immediate action that drives the bottom line.”

Berg explained the O&G industry is increasingly recognizing the need to overcome data quality issues and manage ownership, control, sharing and the use of data.

“But also, the perceived value of use of data has increased dramatically, meaning data insights is an increasingly competitive advantage. A key area in this context is using asset integrity data in performance forecasting and managing aging O&G assets. This may prolong operational life and production by using data insights to ensure operational and safety performance is within acceptable limits,” Berg added.