Choosing the right vehicle security barrier is only the first step to securing a facility. Advanced planning and proper installation are crucial in guaranteeing the barrier provides the level security it was chosen for.

Many factors go into choosing the right vehicle security barrier for the right application. Considerations such as the type of vehicle being stopped, vehicle penetration, infrastructure limitations, and even aesthetics go into the planning, choosing, and eventual installation of products. In order to assure maximum protection and effectiveness, advanced planning and proper installation are crucial.

PlanningThe protection of any facility starts with the development of the threat and risk assessment (TRA) of the facility,

according to Hollice Stone, President of Stone Security Engineering, a physical security consultant company specializing in counter-terrorism protection. By taking into account the history of attacks on similar facilities, the environment where the facility will be located, operational measures that the client is expected to implement, etc., Stone and her team are able to get an understanding of the credible threat and protection level needed. From there, “in order to identify the type and grade of product, and location where protection is required, the security engineer normally interacts with the landscape architect to define vehicular access and circulation around the facility to minimize the effects of these attacks,” said Stone. Three parameters were listed by Stone as those considered when choosing the type and grade of product enlisted: threat type and speed based on the TRA and vector analysis of the vehicular circulation; cost considerations; building environment, including landscape requirements, accessibility, operational measures, building use, etc.

InstallationProper installation of any equipment plays a crucial role in the effectiveness and longevity of a product.

To make the installation process go as smoothly as possible, some companies provide detailed drawings for the installation and rebar cages, if required, so any general contractor can install their units, according to an industry source. The skills required for installation of vehicle security barriers are twofold: general construction skills and integration skills of access control IE card readers, safety loops, and hydraulic or electric actuators. Some companies hire local general contractors to set their barriers in the test track for testing, and then take pictures to verify that the rebar and structure components are set according to the detailed drawings they provided. Manufacturer employees will not be required on site to inspect a product. If general contractors are skilled enough to build buildings, they are skilled enough to set a foundation for their products, stated an industry source.

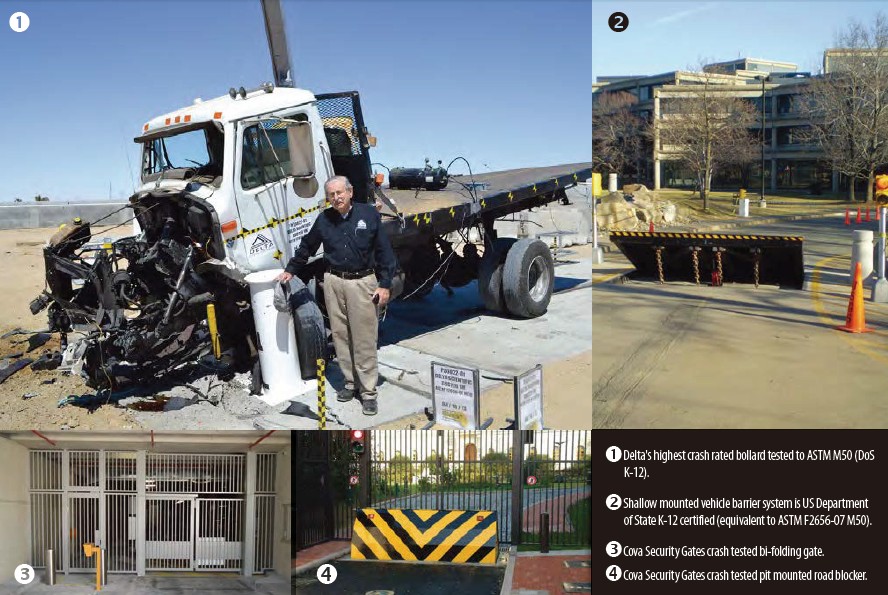

The British Standards Institute (BSI) designed Publicly Available Specification (PAS) 69 as a complimentary.JPG) standard to PAS 68, which governs crash ratings for vehicle security barriers. UK-based companies, ATG Access and Cova Security Gates, emphasize that installation of vehicle security barriers are carried out in accordance with BSI PAS 69 — Guidelines for the Specification and Installation of Vehicle Security Barriers. PAS 69 ensures that products are installed in the field to the same methodology as they were when crash tested, according to Jeremy Tettmar, Sales Director of Cova Security Gates.

standard to PAS 68, which governs crash ratings for vehicle security barriers. UK-based companies, ATG Access and Cova Security Gates, emphasize that installation of vehicle security barriers are carried out in accordance with BSI PAS 69 — Guidelines for the Specification and Installation of Vehicle Security Barriers. PAS 69 ensures that products are installed in the field to the same methodology as they were when crash tested, according to Jeremy Tettmar, Sales Director of Cova Security Gates.

Lucy Foster, Marketing Executive at ATG Access also highlighted the company's utilization of PAS 69 when its in-house civil teams carry out installations. ATG Access has trained its teams of installers and project managers to ensure that they know how everything should go together in the field, said Foster, as well as providing permanent on-going training. From taking samples of concrete to ensure the correct concrete strength, to making sure that the steel design they have devised can be employed to sign off work when the contractor decides to carry out the work themselves, ATG Access checks to make certain the specifications of PAS 69 are met.

Vertical Application

The need for vehicle security barriers in various vertical markets has risen over the last decade along with the indiscriminate possibility of vehicle-borne attacks. High-risk entities such as government organizations, military bases, borders, stadiums, airports, financial institutions, etc. have particularly seen a growing need for hostile vehicle mitigation products.

“Hostile vehicle mitigation products are required in any region whereby [UK] national government security specialists have effectively assessed the potential risk of vehicle-borne terrorist attacks,” said Tettmar. Places concerned with truck bombing threats from terrorists, break-ins using vehicles to penetrate facilities, as well as errant drivers, are all places in need of such products, according to Hamm. For Delta, those clients are mostly government entities, ranging from military to embassies to water utilities to water transportation hubs. An industry source highlighted the need for vehicle security barriers wherever criticalinfrastructure is, especially those related to water, sewers, power transmissions, and communication to name a few.

One sector that the market has seen growth in is “soft targets”. Places such as hotels and retail outlets have recently been installing barriers, according to Hamm. Although, most of Delta's clients are in the government sector, they also featured petro-chemical, public and private utilities, and universities as their other major verticals.

In terms of regional growth, Tettmar emphasized a dramatic rise over the past few years from formerly low-threat regions like Scandinavia, due to increased terrorist activities. Cova also sees growth in areas like South America, the Far East, parts of Africa, and Asia; they also see potential for growth in the Northern European market.

Channels

When it comes to sales, it is important to find strong distributors that understand and can properly and effectively promote the products. Many companies offer warranties where the distributors provide the end users with any product support that may be required within the warranty period. An industry source stated the reason they go to market through distribution channels is because they can provide the end user with local sales and service. “If a project was sold in Chicago and we are in Apex, North Carolina, it is difficult to provide the customer with a 4-hour response time, but our local Chicago reseller can drive over and have a truck with tools and assess the situation,”

.jpg)

said the source.

Other companies like ATG Access and Cova — both of which offer 12-month warranties on their products — also go to market via distributors. “We have a global reseller network, predominately in the perimeter security industry or general security integrators, who resell, install, and maintain our equipment,” said Tettmar.

It is important to point out that vehicle security barriers are not an end-all solution — they are simply one piece of a more complex complete puzzle, which may include alarm monitoring, security cameras, additional perimeter security, and manned security. Additional precautions such as road narrowing and chicanes can also be implemented to slow approaching vehicles and lower the level of needed protection. While barriers, blockers, bollards, etc. are effective in stopping a vehicle from entering a facility, they cannot, however, protect against blasts or ballistic impact.