Rafael Carmisin Duarte, Business Development Manager at Intelbras, thinks that there are three key factors that go into deciding where a factory should be located: government regulations, local infrastructure (logistics and supply chain mainly), and human resources. A place with favorable government regulations, good infrastructure and inexpensive but capable workers would be a good place to establish a manufacturing site. “If we talk about the local benefits on cost, we’re always talking about effects on end-user price, therefore market competitiveness advantage. When talking about the human resources, we consider workers, capabilities and work environment, which will reflect directly on production performance and products' quality. These among other factors will definitely have a result on the reliability of products and in turn, mitigate after-sales problems."

Rafael Carmisin Duarte, Business Development Manager at Intelbras, thinks that there are three key factors that go into deciding where a factory should be located: government regulations, local infrastructure (logistics and supply chain mainly), and human resources. A place with favorable government regulations, good infrastructure and inexpensive but capable workers would be a good place to establish a manufacturing site. “If we talk about the local benefits on cost, we're always talking about effects on end-user price, therefore market competitiveness advantage. When talking about the human resources, we consider workers, capabilities and work environment, which will reflect directly on production performance and products' quality. These among other factors will definitely have a result on the reliability of products and in turn, mitigate after-sales problems."

Location advantages have led to the rise of places like Shenzhen. Shenzhen is a manufacturing hub in the south of China that manufactures many products from different industries. Duarte finds that since there are so many industries manufacturing in Shenzhen and China, the infrastructure is highly developed, and it is very easy to find suppliers of any needed components nearby; however, it is still hard to find qualified ones.

Shenzhen, or rather China, is best known for its relatively inexpensive labor market; on the other hand, this initial lower cost does lead to other concerns and the need for better analysis. “With regards to human resources, people always talk about cost, but they should also consider worker ability,” said Duarte. “In China, the labor is still competitive, but with a high turnover that changes the workforce every 6 months, so workers are neither kept nor invested in for long. If you are able to find a place with capable labor knowledge and skills, and you are able to keep your workers for a long time, it may be worthwhile. Even if you have to pay more for the workers, you will have fewer expenses in the long run."

Shenzhen, or rather China, is best known for its relatively inexpensive labor market; on the other hand, this initial lower cost does lead to other concerns and the need for better analysis. “With regards to human resources, people always talk about cost, but they should also consider worker ability,” said Duarte. “In China, the labor is still competitive, but with a high turnover that changes the workforce every 6 months, so workers are neither kept nor invested in for long. If you are able to find a place with capable labor knowledge and skills, and you are able to keep your workers for a long time, it may be worthwhile. Even if you have to pay more for the workers, you will have fewer expenses in the long run."

Many of the security products on the global market today seem to be manufactured in China, Korea or Taiwan, but this was not always the case. Local manufacturing or assembly, the idea of putting a product together in the place where it will be sold, seems like an anachronism.

How did we get here?

The U.S. spends large amounts of money on security equipment, yet it no longer manufactures much of the technology within the country. Familiar with how manufacturing in security has changed over time is Paul Broome, owner and Consultant with Compair. “The US CCTV Sales Market has changed over time from full line product manufacturers to full line product providers,” said Broome. “It seems that all monitors and cameras are manufactured by non-US manufacturers. For many large US companies, product development is limited to specifying a product's design parameters and shopping for an outsourced developer and manufacturer to take on  the task. A single US company with six DVRs in its product offering may get them from six different OEM companies.”

the task. A single US company with six DVRs in its product offering may get them from six different OEM companies.”

The default now is the collaboration between local and foreign partners, though this can happen many ways. In the U.S., a local marketing, sales and support function in the local language can provide the look and feel of a local product, said Broome. “Collaboration with foreign manufacturers is now an integral part of the US market. Opening markets has made it relatively easy to move the manufacturing effort to the locations of lowest costs. At first the problem was finding a manufacturer who can produce your product for you. Now the problem is deciding which partner to choose from an overwhelming number of offerings. The logistics of making personal contact with offshore partners has been simplified. Just go to any US trade show and walk through aisle after aisle of potential partners.”

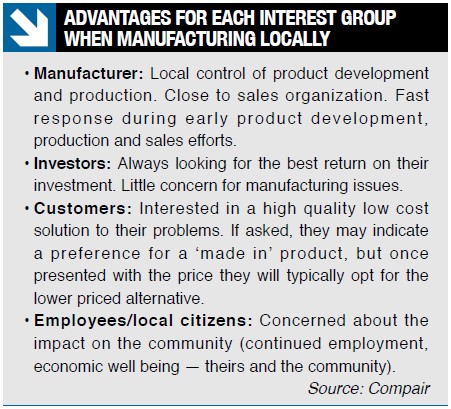

But with this collaboration, is there a way for manufacturing and assembly to be moved towards where the products will be? Outside of price, there are also quite a few intangible effects to local manufacturing and assembly. “To be able to react flexible and agile on market demands and demand fluctuations, a regional manufacturing has a significant advantage for mid and high volume products,” said Michael Jaeger, VP of Operations, Bosch Security Systems. “Regional sourcing is a key aspect to reduce lead times and to gain speed and flexibility.”

“If products are manufactured locally, a big advantage is that they don't have to send the faulty product back to the country of origin for after-sales service,” said Iqbal Singh Jagdeva, MD of Turbo Consultancy Services. “For example, once they manufacture in India, there will be setup for services and maintenance. Presently, if any defect occurs in imported products, the product is often sent back to the manufacturer by paying freight charges and inspection charges. Then after the product is repaired, there are more freight charges and customs duties. Besides the cumbersome paperwork, this is also inefficient.”

Manufacturing within your borders may make it easier to control the manufacturing process. There are less language and cultural barriers. However, the regulations, infrastructure and human capital need to be favorable to local manufacturing as well. “The industrial design needs to consider the capabilities of local suppliers and the available workforce,” said Jaeger. “For products with high complexity and/or low volumes, single source is the preferred approach to manage the complexity best.”

Locally manufactured products may be closer to the local culture, which may allow it to have a wider range of distribution channels in comparison to internationally imported products. “I think that local products have a wider range of distribution channels. Penetration of the local market is easier,” said Duarte. “When distributing imported goods, people mostly focus on the big cities and city centers and miss a lot of the surrounding market — the countryside, smaller cities, and different states. It's easier for local manufacturers; they can go much deeper. They understand the culture, the people; they have the right connections.”

Though it may seem like a conflict for distributors to carry local brands, or even own branded products, along with international brands, often this is not the case. If local brands may be low- to mid-end products, and imported brands are high-end, then distributors may in fact increase their reach, and thereby the reach of all their products, by offering more products for more customers. “A distributor or integrator which is using its own brand is not necessarily a disadvantage — as long as there is no direct competition in the same market and price segment,” said Jaeger.