Security technology used in agricultural applications provides opportunities for manufacturers, distributors and system integrators to think outside the box for business prospects.

Security technology used in agricultural applications provides opportunities for manufacturers, distributors and system integrators to think outside the box for business prospects.

To survive the volatile economy, security providers today can find innovative applications for their technology. In agriculture, the market for surveillance technologies and RFID use has been growing for a decade. Keeping in mind the need to step outside traditional security applications, A&S explores how security technologies are used to enhance precision agriculture, protect aquaculture species and ensure the safety of food processing.

Aerial Insight

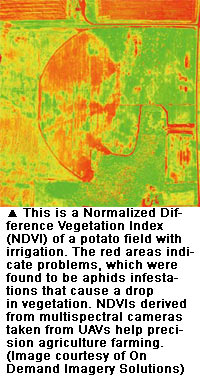

Precision agriculture farming employs aerial surveillance, picking up differences in vegetation with unmanned air vehicles (UAVs). Putting a camera in flight can pinpoint areas of salinity, blight, pest and disease in plants, said Greg Lewis, founder of On Demand Imagery Solutions. To monitor vegetation, UAVs are typically flown in good weather conditions to capture clear images.

Multispectral Imaging and NDVI

Multispectral cameras — which use near infrared bands contrasted with red bands from standard digital cameras — give users a vegetation index, the most common being the Normalized Difference Vegetation Index (NDVI). Through a ratio between near infrared and red wavelengths, the NDVI shows differences in vegetation and allows agronomists to pick out abnormal spots, then proceed to the problem areas, Lewis said.

With ratios from the NDVI, agronomists can differentiate plants from the background, measure stress and understand the general condition of the plant, said Steve Heinold, Executive VP of Tetracam. Abnormal results on the NDVI could indicate hail damage, moles, pest infestation and nitrogen fertilizer deficiency, among other problems. Farmers can insure crops against hail damage, and insurance companies can pay a claim based on information derived from aerial multispectral images that confirm the extent and area of crop damage.

For nitrogen fertilizer applications, multispectral imaging gives farmers a more accurate measurement of nitrogen levels in a leaf, Heinold said. It is important for farmers not to over-fertilize plants as nitrogen disperses from the leaves, polluting surface water and soil.

For nitrogen fertilizer applications, multispectral imaging gives farmers a more accurate measurement of nitrogen levels in a leaf, Heinold said. It is important for farmers not to over-fertilize plants as nitrogen disperses from the leaves, polluting surface water and soil.

Stitching

Digital cameras on agricultural UAVs can be triggered with remote radio signals and GPS receivers, a convenient solution for surveying that reduces manual labor. Due to aviation regulations, UAVs must fly under a certain altitude, making it difficult for cameras to capture a whole field in one shot. As multiple photos need to be taken for a complete image of a field, current software developments focus on image stitching, based on the GPS location of the aircraft. This technology for precision agriculture farming requires powerful and timely software capabilities to stitch together images. Currently, On Demand Imagery Solutions software is developing to overcome rotation problems and automate the stitching process using coordinates from geomeasured images, Lewis said.

Pictures taken by multispectral cameras can also be preprocessed, loaded into tiling or mosaic stitching programs that can then be ground referenced or orthorectified, said Heinold. Using control points from image details — such as lakes, trees and vegetation — algorithms in the stitching software can organize the pictures in the correct order, allowing agronomists the time and resources to check problem areas.

Pictures taken by multispectral cameras can also be preprocessed, loaded into tiling or mosaic stitching programs that can then be ground referenced or orthorectified, said Heinold. Using control points from image details — such as lakes, trees and vegetation — algorithms in the stitching software can organize the pictures in the correct order, allowing agronomists the time and resources to check problem areas.

Growing Niche

As UAVs become cheaper and more available, the market for precision agriculture farming with multispectral cameras will increase, Heinold said. Autopilot controlled GPS UAVs are starting to interest people, and while it is still a niche market, it is growing.

"Manufacturers such as MicroPilot, a specialist in autopilots for miniature UAVs, offer a low cost UAV, which costs about US$7,000 each," said Pierre Pepin, VP of Sales and Marketing, MicroPilot. "The UAVs are designed for monitoring crops and other similar applications, such as cattle monitoring in ranches and forestry."

Salmon Tracking

To preserve and protect aquaculture, RFID can be used to track the migration of salmon. In the agriculture market for passive RFID, fish tracking is small compared to livestock. However, it is an important method for measuring the  survival rate of fish and produces results in a short period of time. Currently, 80 percent of the market for salmon tracking is in the United States, where it is sponsored by the state.

survival rate of fish and produces results in a short period of time. Currently, 80 percent of the market for salmon tracking is in the United States, where it is sponsored by the state.

Dams Pose Danger

There are more than 15 million anadromous fish, commonly called salmon, in the Columbia River Basin, located in the northwestern part of the United States. Salmon develop in fresh water, migrate to the ocean to mature for one to five years, then return to their homes.

To track salmon migration and to prevent them from being sucked into turbines at dams, 5 percent of fish are marked with passive integrated transponder (PIT) tags, each bearing a unique code and submitted into a database, said Zeke Mejia, CTO of Digital Angel. Millions of juvenile fish known as "smolt" are tagged at detection sites, or smolt bypass systems located at dams, then released into the wild.

Turbines at hydroelectric plants present danger to migrating fish, often killing them instantly, Mejia said. The turbines can also suck fish down 10 meters and spit them back out on the surface, making them easy prey for birds. The RFID tagging system was developed in an agricultural application to track salmon and provide them safe passage through dams.

Safe Passage

Every bypass system records the date and time each PIT-tagged fish passes through, checking for survival rates of fish coming from different rivers or lakes,  Mejia said. With this survival rate, researchers can deduce problems such as pollution in lakes, farms or factories that release too much waste or excessive logging. Researchers can also pinpoint the quality of reproduction and conditions of spawning spaces, or where salmon give birth.

Mejia said. With this survival rate, researchers can deduce problems such as pollution in lakes, farms or factories that release too much waste or excessive logging. Researchers can also pinpoint the quality of reproduction and conditions of spawning spaces, or where salmon give birth.

A small net is placed in front of each turbine to catch the fish, sending them through a pipe fitted with an RFID reader, Mejia said. Each bypass system has two 20-inch passages for the salmon, which both have readers to mark fish migration paths. Salmon do not encounter traffic problems because the readers have fast read speeds of 30 milliseconds, allowing millions of tagged fish to swim through on a daily basis.

As each tagged fish's information is gathered electronically, individual fish can be selected for interrogation at dams, streams, hatcheries and acclimation ponds, Mejia said. Antennas detect PIT tag codes as the fish swim by and relay the information to computers for data processing.

Fish can be separated and sent to a nearby lab for interrogation testing, through another set of pipes. "Researchers can then check the ID of the fish, its weight and length, photograph it, and see how much it grew," Mejia said. "Recaptured fish are caught for physical examination, and this process is important in constructing the life history of a fish."

Shrimp Traceability

Aside from tracking live aquaculture, food processing is another facet of agriculture that benefits from RFID technology. As shrimp is a high value product and relies on manual labor for processing, it is one of the most difficult foods to track. In large factories, 50 to 100 tons of shrimp a day is processed, producing tens of thousands of shrimp.

"With so much going on, factory owners need to find out from the raw material that comes in, and the end product that goes out, what happens along the way. They need to trace it," said Dr. Naiyavud Wongkomet, MD of IE Technology. Processing shrimp takes five to 10 separate steps, proving to be an almost impossible task totrace the shrimp without the help of RFID.

Previously with paper tracking, employees had to manually enter each code for every basket of shrimp, raking up thousands of pieces of paper daily. Now, RFID tags can be attached to baskets or tanks, which become RFID-enabled carriers. These carriers will have all information on the shrimp, from position, where the shrimp came from and the information relevant to its deheading, weighting, chilling, peeling and dipping. RFID automates the data capture for these processes, linking the information to traceability software, Wongkomet said.

Other RFID Benefits

In factories with up to 5,000 employees, production control is just as important as tracking the shrimp, Wongkomet said. With information from RFID, factory owners  can track production yields as well as employee productivity. For example, if it takes 30 minutes on average to peel a basket of shrimp and an employee spends three hours instead, the RFID system would report when the shrimp basket was delivered to its next stop. Management can then inspect the situation or employee accordingly.

can track production yields as well as employee productivity. For example, if it takes 30 minutes on average to peel a basket of shrimp and an employee spends three hours instead, the RFID system would report when the shrimp basket was delivered to its next stop. Management can then inspect the situation or employee accordingly.

Food and its processing are placed under tighter scrutiny today. The United States, Japan and Europe have issued legislation on traceability and food safety, and RFID helps companies involved to comply.

"Aside from being greatly beneficial for shrimp traceability, the initial investment of the technology typically takes one to two years to make a full return on investment," said Wongkomet. "We are continuously seeing expansion and adoption of new users. So far, it has been slow, but customers are becoming more interested as success of the technology spreads."

Future Applications

Technologies such as video and RFID solutions clearly have a range of applications not limited to the world of security. In times of turmoil and economic instability, fearless innovation and creativity will expand businesses and see companies through the financial storm.