European guidelines and required testing assure high, consistent quality standards for intrusion detectors.

European guidelines and required testing assure high, consistent quality standards for intrusion detectors.

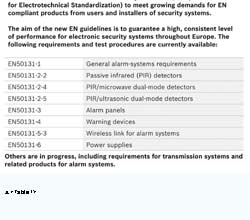

European standards (EN50131) for electronic intrusion detection systems have been in play for years to unify and improve existing national standards. This initiative resulted in a set of regulations that manufacturers, distributors, installers and end users alike must all follow, enabling end users to compare similar products, services and systems.

EN50131 documents standards that devices must fulfill in order to achieve specific security grades, numbered from 1 to 4. Grades reflect security system requirements that aim to overcome various risks as well as ensure environmental protection. They range from low-risk (Grade 1), low-to-medium risk (Grade 2), medium-to-high risk (Grade 3) to high risk (Grade 4). Currently, guidelines covered by this regulation exist for intrusion systems, power supplies, warning devices, wireless elements as well as for general alarm

systems.

What Do Standards Say?

Two sets of guidelines from Table 1 targeting the most popular detectors on the security market are EN50131-2-2 for PIR detectors and EN50131-2-4 for combined PIR and microwave detectors.

The implemented standards raise important issues worth exploring as they help explain the differences between certain requirements for the grading of detectors.

Speed and Positioning Requirements

Speed and Positioning Requirements

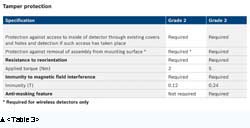

During a general walk test, a series of criteria that takes into account the speed and positioning of an object must be met. Grades 2 and 3 are highlighted specifically in Table 2 to emphasize the differences between the two gradings for categories in speed and position of the detector.

Immunity Iss ues

Section 4.4 of EN50131 is important because it deals with the intrinsic immunity of individual detectors against external influences — specifically the technology's resistance to false alarms. Subsequent sections of the same document refer to tests and specific technical characteristics, which include the following:

* Immunity to air currents: An air current blowing in front of the detector must not cause the IR component to generate any form of intrusion signal.

* Immunity to radiation visible to the IR sensor: Visible radiation to the IR sensor from a nearby light source such as a car headlamp must not cause the IR component to generate any form of intrusion signal.

* Immunity to interference caused by microwave signals from fluorescent lights: Fluorescent light sources near the sensor must not result in the detector's microwave components generating any form of intrusion signal.

* Security against tampering: Table 3 highlights the tamper-protection specifications for each detector grade.

Standardized Test Subject

Standardized Test Subject

The European standards also specify target testing (simulating a human being in a real intrusion situation). The height for this target must be between 1.6 and 1.85 meters and weigh 70 kilograms (+ 10 kilograms). The target must wear tight-fitting clothing that emits heat over more than 80 percent of its surface area at wavelengths between 8 and 14 μm. No metallic objects may be worn or carried.

The average temperature difference between the walk test target and its background must be measured. The temperature must then be measured on surface areas of the test target's body, and the background temperature must be simultaneously measured close to each measured area, including the head, chest, back of hand, knee and foot. This demonstrates the importance of standards ensuring successful intrusion detection for test subjects.

Antimasking

The antimasking feature referred to in Table 3, Section 4.5.5 of the standard indicates that it must be possible for users to identify if the detector is hindered by an application of masking material, or if the detection area and sensor have been covered while the sensor remains inactive, thereby preventing the detection of movement afterwards. This leads to the following requirements:

* When in disarmed mode, the detector must be able to generate an antimasking signal within 180 seconds of the introduction of material being used to mask activity in its field of view.

* Signals or messages must be emitted continuously until the situation is resolved.

* When the device is inactive, normal human movement of one meter per second at a distance of more than one meter should not cause an antimasking signal or message to be generated.

Testing

Testing

Detectors must always meet the required standards and must be in inactive mode for every test. Any changes in signal or message state must be carefully monitored.

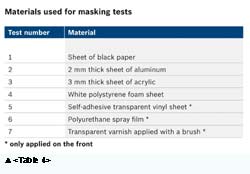

There are several antimasking tests; spray tests are intended to cover the detector lens with an invisible spray material, whereas other antimasking tests focus on solid material that covers the detector (for example, a cardboard box). All material samples must be large enough to hinder detection.

To carry out the spray test, an aerosol dispenser must be used to spray the materials specified in Table 4. Spraying must be intermittent and each spray no longer than two seconds. Following each application, the detector should switch into active mode after 180 seconds and the basic detection test should be carried out. Applications of the external material should be repeated until the detector stops responding or until the antimasking signal is generated.

The material samples specified in Table 4 are applied directly onto the entire front part of the detector. Next, the samples should be applied again across the front of the detector at a distance of 0 and 50 millimeters. Two tests must be carried out: one takes one second to cover the detector lens/window, and the other, 10 seconds. Self adhesive vinyl is applied directly to the front of the detector. As with the spray-on and brush-on materials, after applying each material, 180 seconds should be allowed to elapse to enable the system to settle down before switching to active mode and monitoring for antimasking indication.

Pass / Fail Criteria

Within 180 seconds of the device being masked, a signal or message must be  emitted to indicate an intrusion or fault, and it must continue for as long as the material is in place. Alternatively, both microwave and PIR technologies must continue to operate normally.

emitted to indicate an intrusion or fault, and it must continue for as long as the material is in place. Alternatively, both microwave and PIR technologies must continue to operate normally.

If an individual test fails, it must be repeated twice more. Two passes out of the three tests constitute a success.

The Importance of Independent Testing

After recognizing the impact that adhering to EN50131 standards would have on their sales in Europe, many manufacturers have made rather enthusiastic claims for their intrusion alarms based on self evaluation, but this provides no guarentee of product quality or features. For the EN50131 standards to gain credibility and traction throughout the industry, it is essential for products to be certified by independent laboratories and not by the manufacturers themselves.

Certification carried out by a completely independent laboratory will ensure that the entire security industry — from manufacturers, distributors and installers through to end users — can safely trust the quality and function of the standards. Independent certification will also give recognition to the work of manufacturers'  R&D departments as well as the combined efforts of national and European associations to promote correct implementation of the guidelines. Most importantly, it will mean that end users can be confident in purchasing a product that meets standard requirements.

R&D departments as well as the combined efforts of national and European associations to promote correct implementation of the guidelines. Most importantly, it will mean that end users can be confident in purchasing a product that meets standard requirements.

To this end, many national laboratories, such as CNPP in France, VdS in Germany and ANPI in Belgium, have already initiated product testing based on the available EN standards and technical specifications.