Check in areas at airports might not seem like a dangerous place, but they are more dangerous than one might think. Each year there are several accidents worldwide where someone, usually a young child, escapes the attention of their parents and sneak through the rubber flaps into the baggage belt conveyor system. Apart from frightening the child the many moving parts and conveyor belts in the baggage distribution system can cause serious injuries. That is why the Sabiha Gökçen Airport in Istanbul, Turkey, has installed a thermal imaging safety system that shuts down the conveyor belts the moment anyone enters the baggage handling area.

Check in areas at airports might not seem like a dangerous place, but they are more dangerous than one might think. Each year there are several accidents worldwide where someone, usually a young child, escapes the attention of their parents and sneak through the rubber flaps into the baggage belt conveyor system. Apart from frightening the child the many moving parts and conveyor belts in the baggage distribution system can cause serious injuries. That is why the Sabiha Gökçen Airport in Istanbul, Turkey, has installed a thermal imaging safety system that shuts down the conveyor belts the moment anyone enters the baggage handling area.

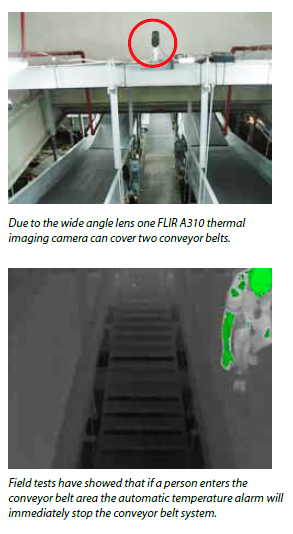

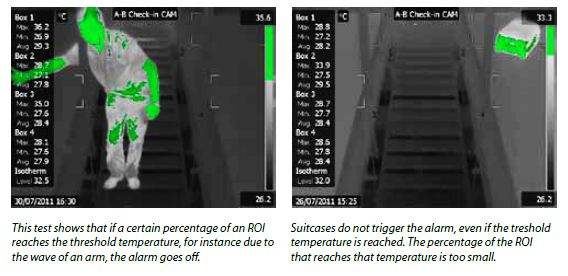

The safety system consists of four FLIR A310 thermal imaging cameras, each covering two conveyor belts leading from the check in area to the baggage handling system. For each thermal imaging camera four regions of interest (ROI's) are defined. A temperature threshold is determined at around 31 °C. For the alarm to go off, however, it is not enough for a small part of the ROI to reach a temperature above the threshold. Over a certain percentage (about 20%) of the area in the thermal image that is defined as a ROI needs to be above the threshold for the alarm to go off.

When an alarm goes off the thermal image is instantly displayed in the control room and it is also automatically emailed to airport officials. This enables them to quickly determine whether it is a person or a piece of baggage triggering the alarm. “If it is a child we can swiftly intervene and bring the child to safety", explains Kaan Türkmen, who is responsible for the airport's baggage handling system. "If there is a false alarm, caused by an exceptionally warm piece of baggage, we can get the conveyor belts running again in no-time. So even if there might be an unwanted alarm the delay will be quite minimal.”

Lowering the unwanted alarm rate

Lowering the unwanted alarm rate

“We have performed a lot of tests and this system works really well”, explains Kaan Türkmen. “Several of our own employees have climbed into the baggage system to simulate the situation where a child climbs onto the conveyor belt and as it turns out the conveyor belt stops running every time we try it.” According to Türkmen there were a few unwanted alarms in the beginning. “Baggage can heat up in the sun due to warm weather to over 30 °C. These warm bags can trigger the safety system. Fine tuning the settings has helped lower the current unwanted alarm rate to near zero. Even so I would rather have a few unwanted alarms then have one instance where a child remains undetected.”

Investigating sensor technologies

Before the FLIR A310 thermal imaging cameras were installed several other technologies were tested, but according to Türkmen none were satisfactory. “For two years we tried other technologies, but no other sensor could accurately distinguish between a child and a piece of baggage, so either the chance that a child would go undetected was too big or the unwanted alarms rate was too high. Then last year one of the airport technicians came up with the idea to use thermal imaging. He knew that portable thermal imaging cameras are used for predictive maintenance inspections and he suggested we should investigate this technology as a basis for our safety system.”

“We turned to FLIR Systems and its local distributor Sentez”, continues Türkmen. “We looked at the possibilities, performed several tests and we were amazed by the results. The FLIR A310 thermal imaging cameras provide high quality thermal images and accurate temperature readings, enabling us to accurately detect the body warmth of a human entering the baggage handling area through the conveyor belt, while keeping the unwanted alarm rate low. I am convinced that thermal imaging is the best possible technology for this safety system.”

FLIR A310 thermal imaging camera

The FLIR A310 thermal imaging cameras that are included in the conveyor belt safety system at Istanbul Sabiha Gökçen International Airport contain an uncooled microbolometer detector that produces thermal imaging with a resolution of 320 × 240 pixels at a thermal sensitivity of 50 mK (0,05 °C). According to Türkmen the FLIR A310 thermal imaging camera is the ideal tool for this safety system. “The thermal image quality is astounding, but other factors are equally important. The wide choice in optics that FLIR offers is crucial for us, since the wide angle lens allows us to monitor two conveyor belts with one camera. The digital outputs allow the system to automatically shut down the conveyor belt if an alarm is triggered. Lastly the software that FLIR provides, FLIR IR Monitor, is very useful. By fine tuning the settings in the software the amount of unwanted alarms was reduced without compromising the detection performance.”

Why FLIR?

According to Türkmen the choice for FLIR Systems was easy. “We did investigate other thermal imaging camera suppliers but none of the other suppliers could deliver the same combination of a high quality thermal imaging camera, a wide choice in optics, local support through the Istanbul based distributor Sentez, user friendly but also feature packed software and the flexible connectivity options that enabled easy integration in our conveyor belt control system. In other words: there simply is no other thermal imaging camera supplier that delivers such a complete package for automation applications.”

For both the installation and the process of fine tuning the system settings the airport relied on FLIR products distributor Sentez. Founded in 1997 the Sentez Group has many years of experience in the installation of camera systems, including thermal imaging monitoring systems. “The FLIR A310 thermal imaging camera is very user friendly and relatively easy to install”, explains Sentez sales manager Emre Budak. “We were able to integrate the FLIR A310 thermal imaging cameras in the conveyor belt control system with relative ease."

Worth the investment

According to Türkmen the thermal imaging safety system has lowered the probability of an accident happening in the baggage handling system involving a child to near zero. “That makes the safety system definitely worth the investment. I therefore think that other airports will start installing such thermal imaging based safety systems as well. It is probably just a matter of time.”

For more product information, please visit:

http://www.flir.com/cvs/americas/en/security/view/?id=55673