Keeping an Eye on Processes

Keeping an Eye on Processes

The use of video cameras on the production line enables real-time monitoring of the entire production process, Ding said. “It is also possible now to monitor staff members for performance, as well as compliance to regulations and company policy. When something goes wrong, the manager can remotely instruct or alert staff members to ensure problems are resolved quickly.”

Furthermore, video surveillance allows a single person to monitor several locations without having to be physically present, whereas in the past, one supervisor was needed to watch each location, Ding said. This drastically reduces the manpower needed for specialized tasks.

Machine Vision

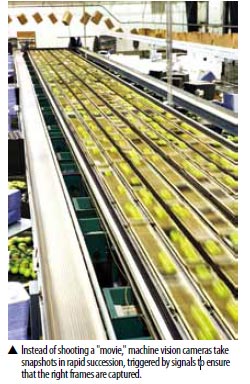

Machine vision cameras can also be utilized to monitor the production line for quality issues. There are two differences between security cameras and machine vision cameras, said Hardy Mehl, Director of IP Business for Basler. “For machine vision, there is a very controlled environment, which means there is stable lighting and the camera looks at very defined objects. The camera or video system does not have to work in challenging light conditions. This is a big difference from the security world, where you always have the sun coming up or shades or reflections, so security cameras are more optimized to changing, dynamic environments.” The other is compression, as all network cameras use compression algorithm such as M-JPEG or H.264. “Typically in the industrial automation world, raw data is transmitted,” Mehl said. “This is a big difference that has implications on which interface to use between the camera and the PC. In the industrial world, you need much higher bandwidth since the data is not compressed. The computer is looking at the image, and you need the absolute best quality in terms of signal-to-noise ratio to calculate and get every little detail.”

Machine vision cameras can also be utilized to monitor the production line for quality issues. There are two differences between security cameras and machine vision cameras, said Hardy Mehl, Director of IP Business for Basler. “For machine vision, there is a very controlled environment, which means there is stable lighting and the camera looks at very defined objects. The camera or video system does not have to work in challenging light conditions. This is a big difference from the security world, where you always have the sun coming up or shades or reflections, so security cameras are more optimized to changing, dynamic environments.” The other is compression, as all network cameras use compression algorithm such as M-JPEG or H.264. “Typically in the industrial automation world, raw data is transmitted,” Mehl said. “This is a big difference that has implications on which interface to use between the camera and the PC. In the industrial world, you need much higher bandwidth since the data is not compressed. The computer is looking at the image, and you need the absolute best quality in terms of signal-to-noise ratio to calculate and get every little detail.”

Security cameras are different, as every detail is not essential or practical. “You need high-resolution, but typically you need compressed images that are just good enough, and you need lower bandwidth because you store for a long time,” Mehl said. “In the industrial environment, you don't transmit live streams, but rather you shoot images. You make snapshots and you transmit the snapshots in very high frequencies.” The two types of cameras are not interchangeable in most cases, but due to the technological development and market development, there are some applications that overlap. “The performance of network cameras, in some cases, is good enough for industrial purposes,” Mehl said. “For example, they are cheaper or give an advantage. However, in most cases, there are really two different demands on the customer side.”

Bringing Disparate Systems Together

One clear management level trend regarding access control, and security in general, involves manufacturers taking a holistic approach to access control technology, processes and policies to protect their most essential operations. “The need for a global approach is driven by the high level of acquisition activity among manufacturers over the last 10 years and the rise in risk and threat levels these companies face,” McCaughey said. “From a security perspective, acquiring companies also means acquiring their security infrastructure, policies and their risk profile. As the chief security officer, anything more than one security infrastructure and set of security operating policies and processes builds inherent risk into your business. There is more to manage and more potential holes in your security perimeter.”

One clear management level trend regarding access control, and security in general, involves manufacturers taking a holistic approach to access control technology, processes and policies to protect their most essential operations. “The need for a global approach is driven by the high level of acquisition activity among manufacturers over the last 10 years and the rise in risk and threat levels these companies face,” McCaughey said. “From a security perspective, acquiring companies also means acquiring their security infrastructure, policies and their risk profile. As the chief security officer, anything more than one security infrastructure and set of security operating policies and processes builds inherent risk into your business. There is more to manage and more potential holes in your security perimeter.”

Adding Video to Access Control

Integrating access control, security management systems and video surveillance creates significant efficiency gains in industrial and manufacturing environments, said Aaron Kuzmeskus, Director of Security Channel Development, Buildings Business, Schneider Electric.

For example, access cards used in combination with visual verification of the cardholder enable quicker throughput of workers without requiring someone to check ID badges, Niederberger said. “This is applicable at the security perimeter of a plant and within the plant itself.”

Video surveillance enables security operations to have eyes on an event, even when they are not physically present. This manifests itself in two ways, Kuzmeskus said. “One is the ability to assess quicker an alarm event or situation, and a safer manner of assessment in areas where dangerous substances or machinery be may be in use.”

Secondarily, video verification at access points can lessen the financial burden of stationing guards at sensitive entry or egress portals or to physically verify that credentials are being used properly, Kuzmeskus continued. While biometrics provides good identification, it can be problematic in areas that require personal protective equipment, such as gloves and face shields.

Integration between access control and video enhances productivity, as it can corroborate staff access records with video footage. A common example of poor productivity is staffers taking frequent smoke breaks while claiming to be carrying out other tasks, Lim said. “Another example I came across is for a sterilization room, where a customer had utilized our system to control. According to company policy, the time needed for staff to be sterilized prior to entering a clean room environment. However, some staff members deliberately shortened their sterilization period. As the staff are all wearing suits, without both records for exit access and video information, it would be difficult to determine which staff members violated company policy.”